Selecting a partner for oils and greases is a business decision with direct impact on uptime, compliance and operating cost. The best choice is rarely the cheapest drum on the day. It is the lubricants distributor that can prove product coverage, technical depth and reliable logistics, backed by recognised standards and clear documentation.

1) Product range that matches plant

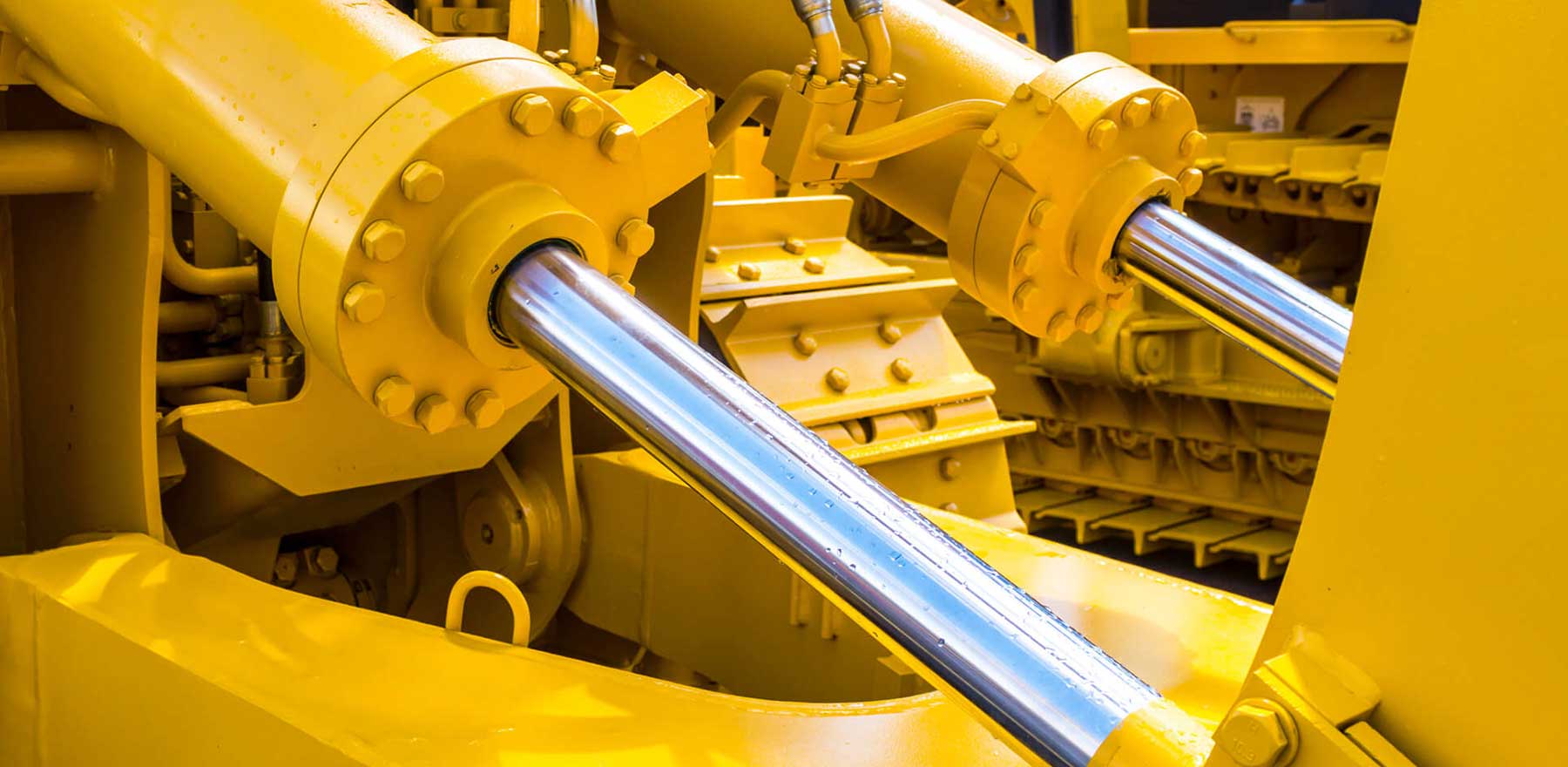

Start by mapping your equipment list to a supplier’s catalogue. You need breadth across hydraulic oils, compressor fluids, industrial gear oils, greases, coolants and specialty lines for food, mining, marine or power generation. LSA Oils publishes an industrial and automotive portfolio spanning those categories, giving Australian operators one place to source plant-wide lubricants with consistent data sheets and support.

Coverage matters because mixed brands complicate storage, compatibility and audits. A well-structured range lets you standardise on fewer SKUs without compromising specification. It also makes cross-site deployment easier if your business operates in multiple locations.

2) Standards and certifications

Quality and governance are not marketing slogans. Ask prospective suppliers which management systems they operate and request current certificates from accredited bodies. As a baseline, ISO 9001 addresses quality management, ISO 14001 covers environmental management and ISO 45001 focuses on occupational health and safety. These standards indicate process control across ordering, storage, decanting and service, not just what is written on a label.

Where food or beverage production is involved, check for product stewardship such as ISO 21469 or NSF programmes that govern the formulation and manufacture of food-grade lubricants. In parallel, confirm that recommendations align with recognised product families and classifications like the ISO 6743 series used for hydraulic and other industrial fluids. Clear, published frameworks reduce ambiguity when you switch products or train new staff.

The Australian Lubricant Association provides industry resources and training. While membership is not a substitute for certification, it signals engagement with local best practice and policy settings.

3) Technical support

Look for engineers who will visit site, complete a lubrication survey and produce a consolidated register with intervals, products and volumes. Beyond the first pass, you should expect access to data sheets, safety documentation and selection tools. LSA’s Oil & Lube Guide is a useful example of a structured recommender that helps match applications to specifications and reduces guesswork for maintenance teams under time pressure.

Good suppliers also assist with rationalising overlapping grades, grease compatibility checks, flushing plans during changeovers and advice on handling contamination, varnish or foaming. The payoff is fewer unplanned stops and cleaner audit trails.

4) Delivery and inventory

An oils supplier must deliver on time, in the right packaging, and with the right paperwork. That means a distribution footprint, stock on hand and the ability to service metro and regional sites. LSA provides a national store-locator and stockist network, making it easier to pin down lead times and collection options near your depots. Use tools like this to validate coverage before you commit, especially if your sites are spread across states.

Ask practical questions: Can they guarantee next-day emergency deliveries within your radius? Do they offer decanting into clean totes, colour-coded transfer gear and sealed dispensing systems? Can they hold safety stock against your forecast?

5) Documentation and comparison tools

Confidence grows when product claims are easy to verify. Expect current technical data sheets and safety data sheets, along with clear references to viscosity grades, performance levels and any OEM approvals. LSA’s product pages group families by application, which helps maintenance planners compare options within a category and avoid mixing incompatible chemistries. If you maintain a multi-site register, align your internal codes with the supplier’s published ranges to remove ambiguity at the storeroom door.

6) Service, training and continuous improvement

A relationship does not stop at delivery. Useful add-ons include toolbox training, storage and labelling audits, oil condition monitoring, failure analysis support and seasonal reviews of viscosity selection. The right partner also keeps you informed about regulatory changes or new standards affecting how you select, store and dispose of lubricants in Australia. Industry bodies such as the ALA can be a reference point for education and events to keep your teams current.

Checklist for procurement and maintenance leads

| Area | What to verify | Why it matters |

| Range & coverage | End-to-end catalogue for your plant, not just engines | Fewer SKUs, simpler training |

| Standards | Valid ISO 9001, 14001, 45001 certificates | Process control, safety and ESG alignment |

| Food-grade needs | ISO 21469 or NSF programme where relevant | Hygiene assurance and audit readiness |

| Classification language | References to ISO 6743 families | Easier cross-reference and substitutions |

| Technical support | On-site surveys, registers, data sheets and selection tools | Better reliability and fewer errors |

| Delivery & footprint | Stockists, lead times, emergency coverage | Less downtime waiting on supply |

LSA Oils combines product breadth with practical tools and a national reach. Its public materials show an industrial and automotive catalogue with clear categories, plus a store-locator and an application-driven selection guide that make day-to-day decisions faster for supervisors and fitters. Use these assets to validate specifications, standardise your lube room and keep records tidy for audits and warranty claims.

If your operation needs a dependable partner for changeovers, storage upgrades or fleet rationalisation, talk with LSA’s oil specialists about site surveys and a phased rollout plan. That approach turns many small wins into measurable gains in uptime and safety over the maintenance year.